Flexible Support Services for Blade Production Facilities

At Ruhr Industrial Services, we bring precision and expertise to every facet of blade production, ensuring top-notch results.

Our comprehensive range of services includes:

- Rotor Blade Design and Materials Assignment: Meticulous assignment of blade shape using advanced materials like glass fiber, balsa wood, and structural foams.

- Segmented Blade Production: Precision crafting of blade segments through vacuum injection and hand wet lamination.

- Cleaning, Maintenance, and Repair: Post-production focus on cleanliness, maintenance, and advanced repair techniques.

- Filling and Coating: Careful application of high-quality materials for optimal protection against environmental factors.

- Erosion Protection Films: Application of specialized films to safeguard against erosion.

- Weighing and Balancing: Prioritization of weighing and balancing for optimal functionality.

- Quality Assurance and Finishing: Commitment to finishing coated surfaces to meet industry standards.

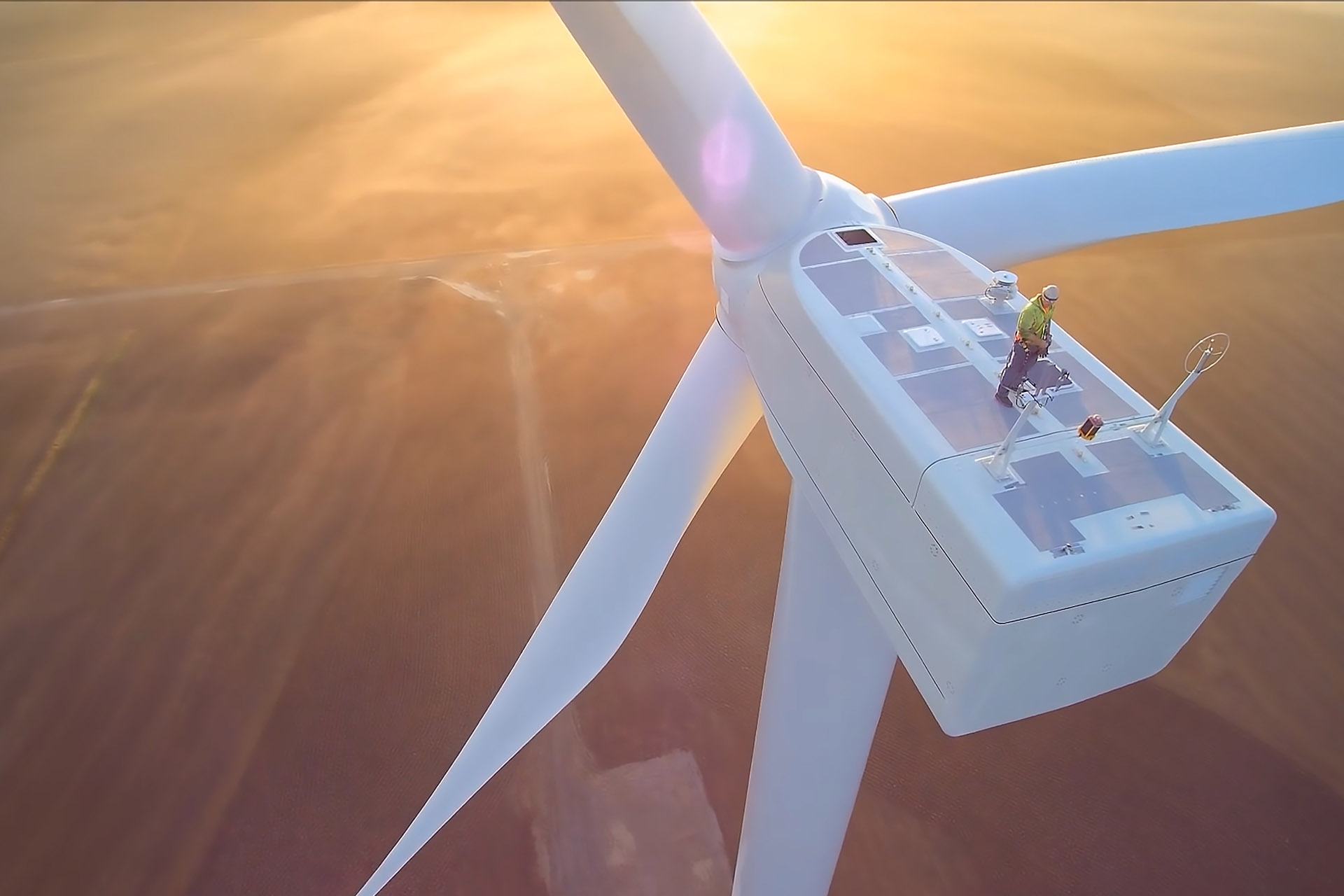

- Complete Coating with Rope Access Techniques: Efficient and thorough coating utilizing advanced rope access techniques.

- Tower Paint Damage and Corrosion Repair: Specialized services addressing tower paint damage and corrosion.

- GRP Repairs and Composite Work: Capabilities include GRP repairs and composite work to reinforce durability.

- Surface Repairs and Grinding: Specialization in surface repairs and grinding for aerodynamic efficiency.

- Adhesive Residue Removal and Inspection: Meticulous removal of adhesive residues and thorough inspections post-manufacturing.